Our Initiative and Impact

As a common good, water is a shared natural resource and we believe that the smallest of efforts add up to make a huge difference. At Glenmark our intention is to improve water management by focusing on optimization, reuse and recycle of this resource.

Believing in the principle of 3R’s, we have made efforts to reduce our water consumption by adopting best practices, alternatively reusing and recycling the treated wastewater in cooling towers, boilers and landscaping.

Our freshwater consumption for utilities, domestic and gardening has reduced over the years with increase in process water consumption. We have invested in Rain Water Harvesting (RWH) structures in our facilities at Goa, Indore, Nalagarh, Baddi, Taloja and Mahape. The total capacity of our RWH structures can replenish 10 percent of our annual freshwater demand.

WASTEWATER MANAGEMENT

One of the most promising efforts that stem from the global water crisis is reclamation and recycling of industrial and municipal water. In the context of increased fresh water demand for industries, wastewater treatment and recycling requires greater focus. We understand that ‘wastewater is a resource’ that can be adequately treated to successfully satisfy most water demands, simultaneously achieving pollution prevention and reduction in wastewater discharges.

We have adopted Zero Liquid Discharge (ZLD) approach in our Aurangabad and Sikkim plant. Good quality water is reclaimed from wastewater at this facility and is available for recycle in boilers, cooling towers and toilets. In rest of our facilities wastewater is treated and recycled for gardening purposes within our premises. These efforts help us meet 38 percent of annual freshwater needs.

The world over, governments are urging industry to switch to renewables. Today, many countries and corporations rely on wind and solar to power their needs. Our operations today incorporate innovative systems, processes and products designed to optimize use of energy. In many cases we have made a conscious shift to utilize energy from renewable sources.

ENERGY CONSUMPTION AND EFFICIENCY

Our operations today incorporate innovative systems, processes and products designed to optimize use of energy. We have implemented a number of initiatives to reduce consumption. We introduced new and innovative interventions in the areas of lighting, pumps and motors, power factor, automation, refrigeration system and fuel. In many cases we have made a conscious shift to utilize energy from renewable sources.

SOME OF OUR ENERGY SAVING INITIATIVES:

Energy Efficiency Projects across plants

Automation :

- Installed heat Pump to replace electrical heaters for humidity control

- Automated dust collector operation with remote control

- Digitization of HVAC system is in progress to maintain precise air quality and achieve energy saving

- Installed motion sensors for office lighting

Pumps- Motors & Blowers :

- Optimised AHU operation during non-working hours by installing timer control

- Optimised operation of HVAC system during non-working hours of manufacturing, packing sampling & dispensing areas

- Optimised operation of dust collector system during non-working hours of production & packing areas

- Installed energy saving fans for Utility cooling towers

Fuel :

- Saved energy by eliminating pre-heating requirement of FO as it is replaced with Biofuel.

- Installed flash vessel to utilize flash steam from ATFD

- Installed steam purging system with feed water tank in Boiler house to raise boiler feed water temperature

- Installed steam condensate recovery system and used recovered hot water to heat boiler feed water.

Refrigeration, Heating & Compress Air System :

- Used chemical (frigitech) in chiller system to improve cooling efficiency

- Reduced compressed air requirement by installing air regulators in washing areas.

- Interconnected two hot water generators to optimized their operation to one unit at a time.

Our facilities run on diverse energy sources of renewable and non-renewable nature. Biodiesel is used at our Aurangabad and Nashik facilities. Baddi and Nalagarh rely on a mix of Liquified Petroleum Gas and HSD and remaining facilities at Sikkim, Goa & Indore are using HSD/LDO.

Efforts in conserving and efficiently using energy and fuels have positively impacted our contribution to the local air quality and climate change. A key enabling factor has been the drive from employees who have been instrumental in implementing these initiatives.

The amount of waste produced worldwide is 4 billion metric tonnes each year and expected to double by 2025 owing to economic and population growth. About 70 percent of this is dumped into landfills or open dumps. Each type of waste creates different hazards, adversely impacting the health of communities and ecosystems alike.

Our strategy is to handle each stream of waste with specific solutions, thus managing and disposing waste with minimum impact. We have focused on four waste streams including hazardous waste, non-hazardous waste, e-waste and domestic waste from our facilities.

HAZARDOUS WASTE AND CO-PROCESSING

At Glenmark we pursue best in industry practices for disposal of hazardous waste.

Our target is to reduce the waste generated and to devise innovative ideas to send zero hazardous waste in to the landfill. We have initiated this process by co-processing the Hazardous waste. Our plants like Goa, Indore, Baddi, Sikkim, Nalagarh are engaged in Pre-processing & Co-processing of Hazardous waste and aiming to achieve 100% disposal of Hazardous waste through cement kilns.

DOMESTIC WASTE

Glenmark understands the importance of segregation of waste at source. By doing so, we not only salvage valuable material present in the waste but also divert this waste from going into landfills. It also helps reduce greenhouse gas emissions that are otherwise emitted if not composted. In our facilities, segregated waste is converted into manure via vermicomposting.

E-WASTE

We at Glenmark understand the importance of conserving virgin natural resources and our commitment towards this cause is evident from the numerous initiatives that we have undertaken. Our offices are a constant source of waste, especially e-waste We have reduced the amount of e-waste going to landfills by encouraging refurbishment and reuse of electronic components.

While e-waste has been a source of livelihood for the urban poor, it is often one of the major contributing factors for severe risks to human health and the environment. Most workers engaged in the waste sector are not aware of the risks involved. The practices adopted in recycling waste and recovering materials are rudimentary, involving acid bath heating, open burning and indiscriminate use of chemicals without following any safety norms. These are often conducted in the by lanes of the city, making them dangerous and hazardous for the environment and human health.

By sending the e-waste to authorised recyclers we are assured of safe disposal of the e-waste generated in our offices, plants and R&D sites, thereby reducing the environmental pollution and health risks to the society.

We at Glenmark have promoted resource efficiency through waste management in an environmentally safe and socially responsible manner by adopting a combination of treatment options. These include e-waste recycling, in-house composting, hazardous waste co-processing, coupled with creating awareness through various environmental campaigns.

MANAGEMENT OF WASTE SOLVENT

Scarcity of resources is driving the need for efficient use. Our commitment to conserving natural resources includes making best use of all materials. At Glenmark, we recover the solvent used in our processes for material efficiency and resource recovery. Pharmaceutical processes require solvent as a medium for separation and purification, washing of product and cleaning of equipment. Significant quantity of the spent solvent is generated from these processes. Such a large volume of spent solvent cannot be reused without decontamination.

Solvent recycling in API facilities is possible after quality assurance unlike other manufacturing facilities that strictly avoid recycling of materials. Spent solvent disposal to the environment is not advised as it can be toxic and non-biodegradable. Recovering good quality solvent for recycling in API manufacturing process is also a challenge as it requires complex design and large set up to remove various contaminants present in the spent solvent.

We have been strengthening our ESG focused approach by committing to external initiatives and taking proactive measures. Our ESG strategy is aligned with the UN SDGs and aims to enhance our contribution to the global sustainable development agenda. We have also been communicating with our stakeholders on our ESG performance through GRI standards aligned sustainability reports annually.

Our ESG centric approach has also been recognised by globally acclaimed benchmarks such as the Dow Jones Sustainability Index (DJSI). The acronym “ACE” captures the essence and key facets of our ESG strategy. It is our vision to drive tangible ESG impact and work towards developing programs that help us emerge as a global benchmark.

We have conducted the supplier assessment through third party auditors on the basis of Glenmark supplier sustainability protocol in which there is an audit tool with rating system. Assessments of 7 suppliers were conducted by third party auditors and almost 1200 suppliers were covered by self-assessment using the audit tool and on the basis of their response, they were rated as “Beginner”, “Implementer” or “Stewardship”.

Suppliers / Vendors gets audited on the elements like

a. Ethical responsibility,

b. Environmental Responsibility,

c. Social Responsibility

Below are some details on our ESG Performance: –

- Energy conservation of 23,902 GJ in FY22

- 6% of our electrical energy derived from renewable sources of energy & Scope 1 emissions stood at 14,967 TCO2e

- 29,733 trees planted cumulatively since FY 13

- 1,74,848 KL of wastewater is recycled, and 15,11,061 KL of water saved since FY 14

- 49% Hazardous waste generated is co-processed

- 100% EPR target achieved to recycle / reprocess plastic waste

- We have covered all suppliers under a ESG self-assessment program

- We have tailored a sustainable supply chain protocol to drive ESG focused excellence

- Zero cases of fatalities and occupational disease in the last 5 years

- Positively impacted over 2.6 million lives through our CSR interventions

- Over 80% of Board members have extensive experience in pharmaceutical industry

- Dedicated Human Rights third-party assessment conducted

FOCUS AREAS IN ESG strategy :- - Climate change

- Water management

- Waste management

- Employee wellbeing and development

- Product safety, quality and accessibility

- Community development

- Responsible supply chain management

- Risk management

- Business ethics

- Digital tranformation

- Promoting innovation

ESG Commitment to SBTi :-

- We have made commitment to SBTi and taken targets and submitted commitment letter for below targets

– We aim to emerge as a carbon-neutral enterprise by 2030 (Scope 1 and Scope 2)

– We aim to achieve water neutrality by 2025

– We aim to achieve zero waste to landfill by 2027

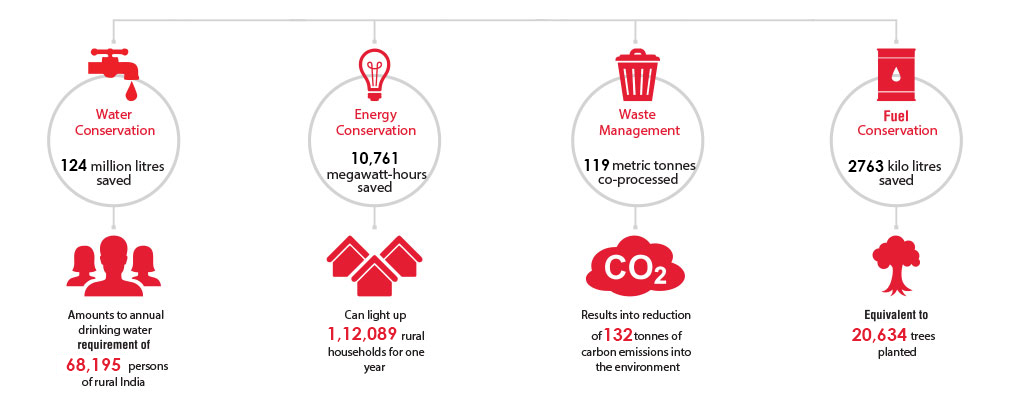

SOCIO-ENVIRONMENTAL IMPACT METER